I’m writing this sitting in an airport watching the Strade Bianchi live. What?! Air travel and pro cycling? The world is still pretty scary compared to seven months ago, but it sure is nice to see my favorite sport back in action. And crazy news flash – racers in the Strade Bianchi are riding gravel on 28c tires. Who in their right mind would ride gravel on anything smaller than a 40? These guys must have not gotten the memo that in order to ride a bike on a dirt road you need at least a 38c tire and a handmade handlebar bag stuffed with snacks and a little weed. Hahaha, I kid, I kid. Who doesn’t like a bag full of snacks and a little weed on the front of their bike?But the point of this Tech Tuesday isn’t to critique what’s cool – or high rather – in the cycling industry, it is to talk about the tech that goes into building our frames.

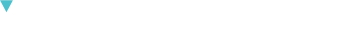

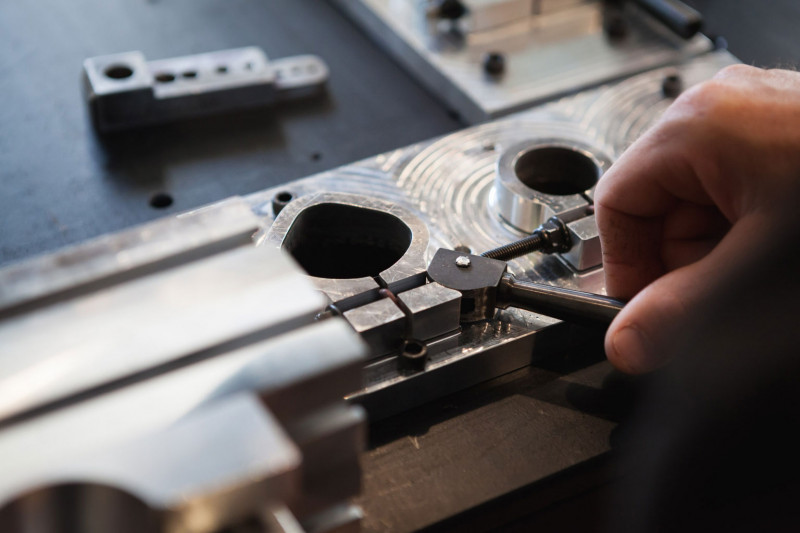

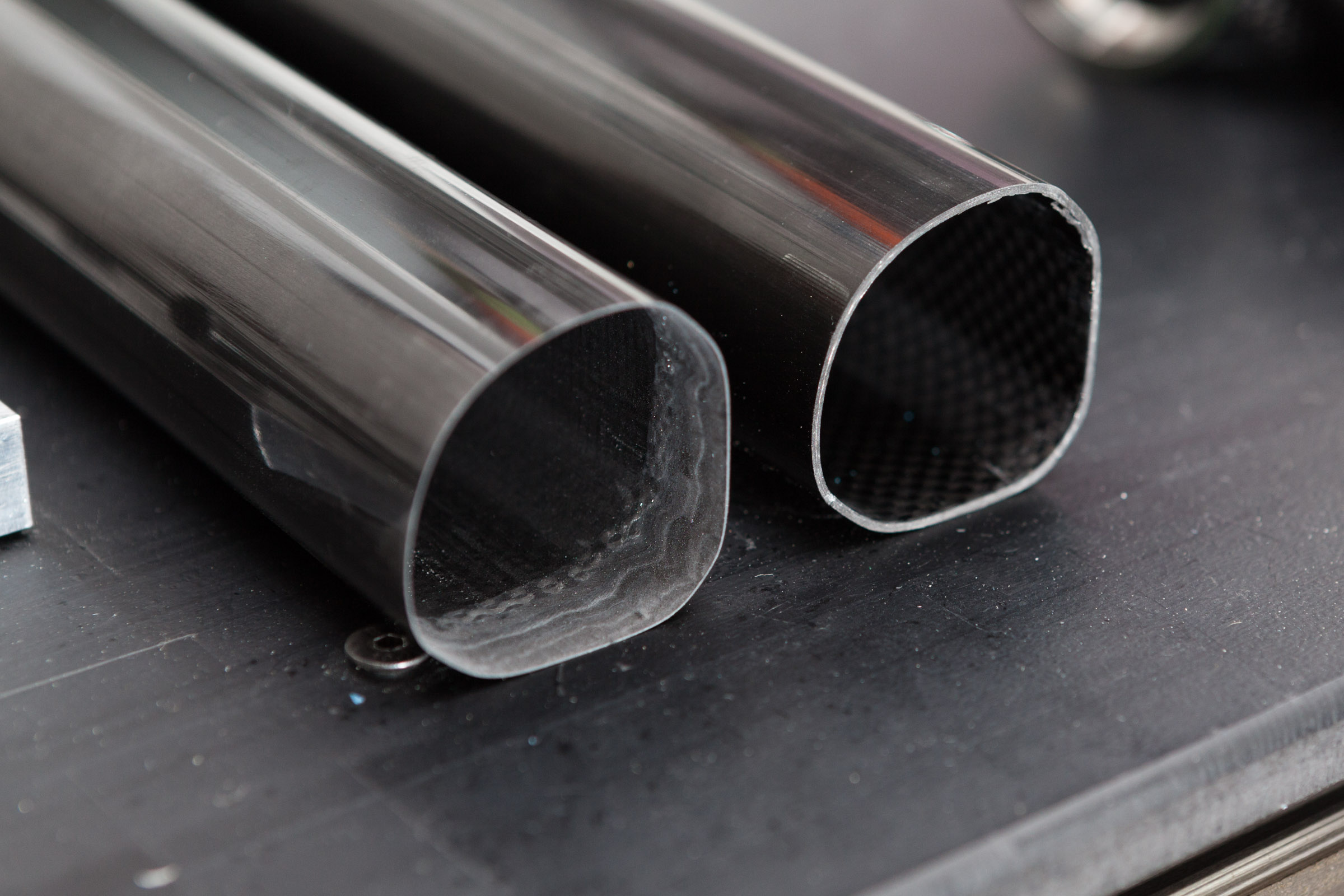

We’re excited about our recent addition of this CNC router. Why do you need a CNC router when you already have a 3-axis CNC machine? This Laguna CNC router is specifically used to chamfer the insides of RM3 frame tubes. The chamfer on the internal surface of every frame part is critical. The tubes are engineered to have a specific carbon ply taper at the male / female bond area. The male end is also tapered, and to effectively bond two carbon structures in a way that appropriately distributes the load a consistent chamfer is key. Really, the only way to do this quickly and accurately is with a CNC.

A CNC router is the perfect tool for this. An enclosed 3-axis CNC like our HAAS VM-3 won’t work because the tubes do not fit vertically inside the machine. A CNC lathe could work, but that’s a little overkill and setup would take forever. This Laguna CNC router is a perfect solution, particularly because there is a lot of open space below the table where the tubes can sit vertical. Now we can load every frame part that needs chamfering and run a single program to machine every surface. Perfect parts require perfect tapers. Before the addition of the CNC this was once a tedious and time consuming process, but now can be performed quickly and accurately.

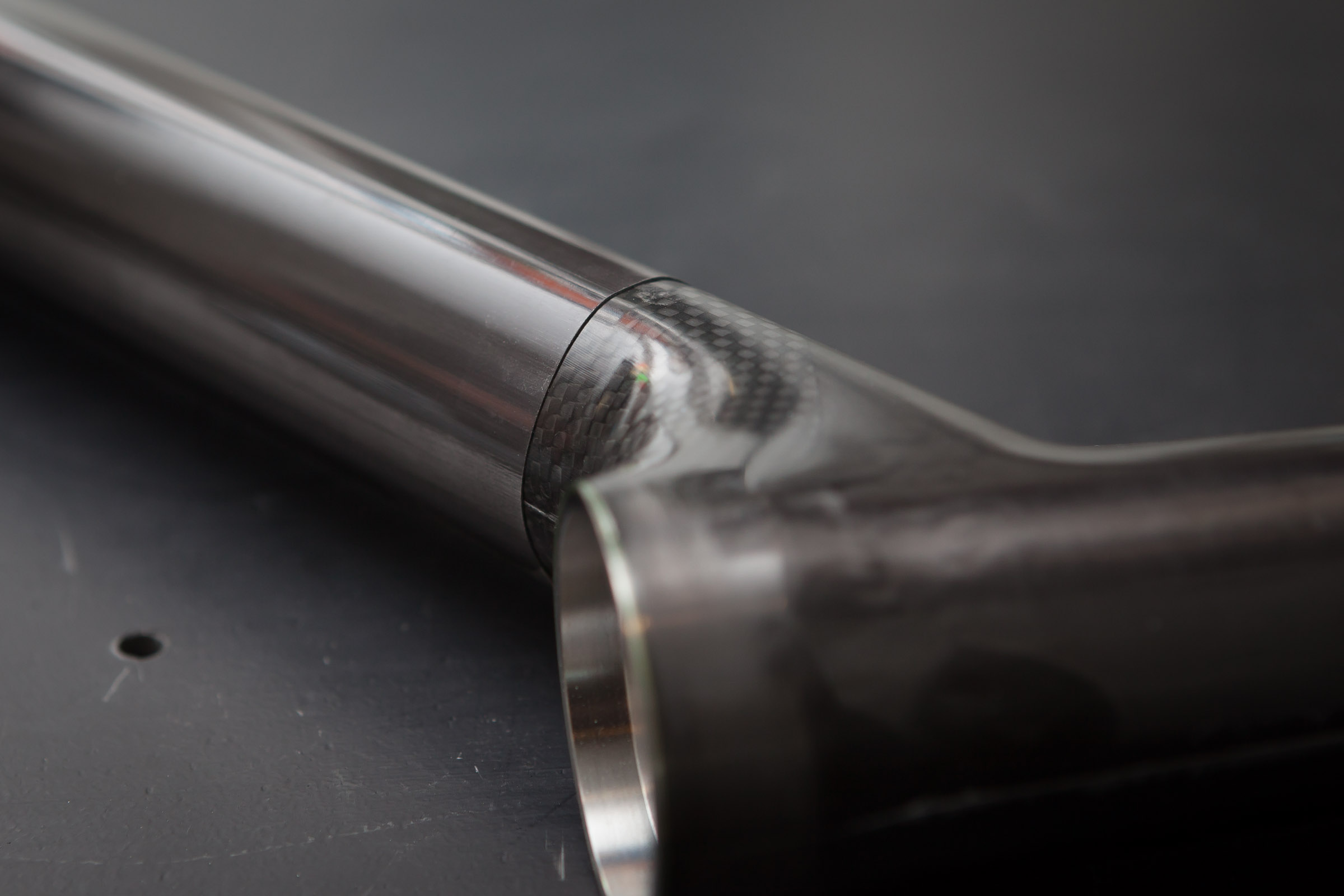

After the taper is added Tubes fit perfectly with the junction

I’ve always admired machinists, and if I had it do over again I would’ve spent time learning to be one rather than getting a degree in history. I used to share shop space in Portland with Andy Newlands who makes Strawberry Bicycles. Andy is more of a machinist than framebuilder, and consequently builds incredible bicycles. Strawberry bikes are basically machined frames. Every small part of the bike is made on the mill or lathe rather than “handcrafted”, and thus creating precision works of art. Since working alongside Andy I’ve always had that precision in mind when creating Argonaut frames. With the addition of the CNC router and reducing the amount of hand processes we’re able to automate steps and create a better more constant final frame.

Thanks for reading.