5.26.2020 – Words by Ben Farver

Make it, break it, do it again. That pretty much sums up our testing protocol over the last three months. When the Argonaut team and I decided to take all composite production in-house it became apparent that robust and comprehensive impact and fatigue testing capabilities would be imperative.

There are a few bicycle testing labs across the US that do an excellent job, and using one of these labs would be a more economical solution. The downside is time. A testing protocol takes exponentially longer using a 3rd party primarily due to transit time. A single frame takes at least a few days to get to the test lab, then tested, and a few days back in the best case scenario. When testing multiple frames those days waiting for crucial data quickly turn into weeks and even months.

Our R&D process has three legs, each critically important for developing new product. Design, engineering, and testing. During the design phase Steve Domahidy creates the ideal form. He then works with Mike Olson to engineer the tooling. Following that comes the layup design for the part, again done by Steve. Once we have a prototype part, we try to break it using either a destructive impact test or cycle fatigue test.

Our test lab has two impact tests made by Chris Fitzpatrick that meet the ISO, or International Organization for Standardization, criteria for falling mass and horizontal impact. The falling mass test is intended to mirror the forces of a rider in a head on collision, and the horizontal impact mirrors the forces of a rider dropping from a high curb or ledge.

ISO 4210-6:4.1 Falling Mass

ISO 4210-6:4.2 Falling Frame

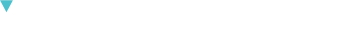

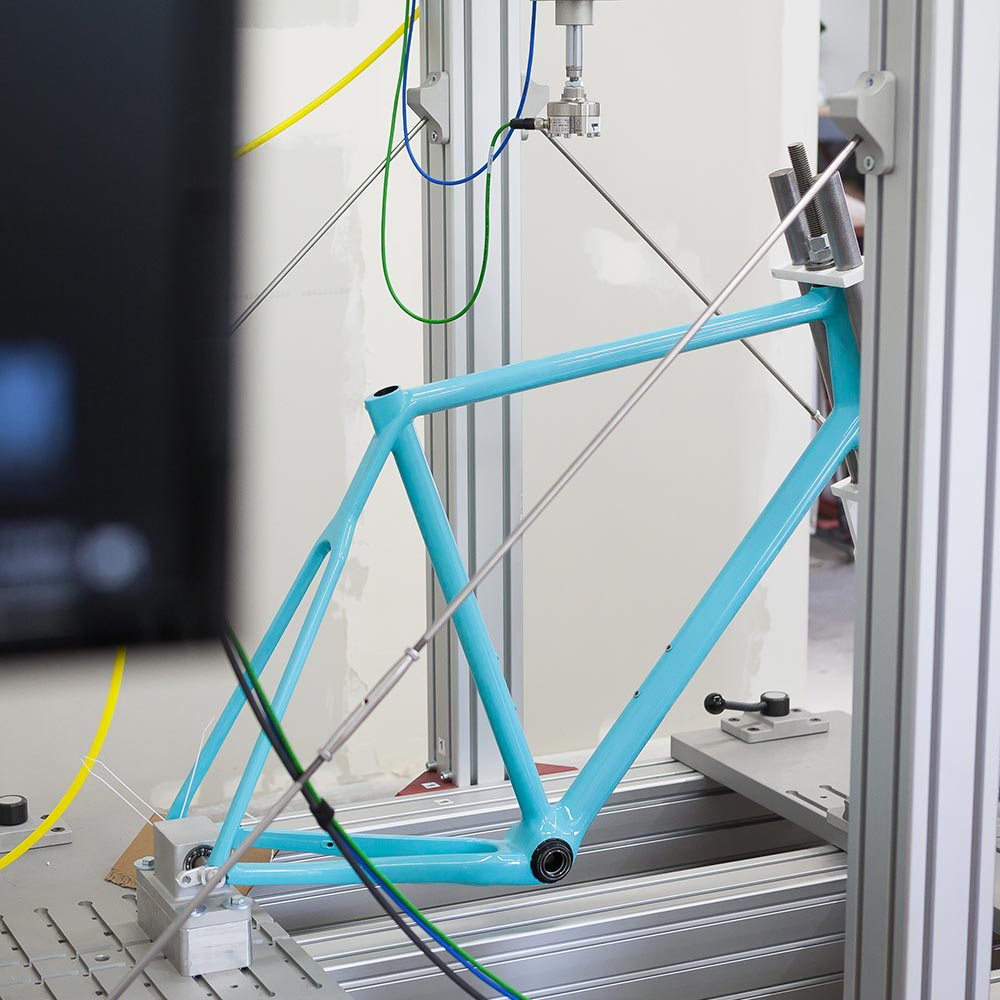

Impact tests are great for making sure that Argonaut road frames are structurally viable and safe. Equally important is the validation of long term viability. Our fatigue testing machine is a thing of beauty, built by LiTeM and imported from Italy. With this machine we perform ISO 4210-6:4.3 that mimic pedaling forces, ISO 4210-6:4.5 vertical weight of the rider, and ISO 4210-6:4.4 for the horizontal stresses the rider puts on the frame. Each test is at least 50,000-100,000 cycles, and the forces of each cycle are the maximum the frame would expect from a very large, very powerful rider once or twice during a long ride.

LiTeM Cycle Fatigue Fixture – performing pedal fatigue and horizontal fatigue tests.

We built this test lab to make sure that first, our frames are safe, and second, so that they’re reliable. Argonaut road bikes will last a lifetime. I know this because we put our frames through a lifetime of abuse here in our lab.

Thanks for Reading.