Titanium

I love titanium. Everything is better with titanium. I would put titanium on my breakfast cereal if there was a chance it would slowly turn me into something like Wolverine. It’s light, super strong, and extremely corrosion resistant. When aliens land on Earth long after humans have gone extinct our titanium implants will be the only evidence of our existence.

Honestly, if I were to ride a bike other than an Argonaut it would be custom Ti, or a Bastion – those things are absolutely gorgeous. Where titanium falls short in comparison to carbon is the fact that it is an isotropic structure, and carbon is a anisotripic structure. Titanium is plenty light to make a great riding road bike, but unfortunately it can’t be made to have dissimilar flex characteristics as discussed in detail here.

Aluminum is the workhorse of the bicycle industry, and 6061 and 7075 alloys are widely used in handlebars, stems, seatposts, and all kinds of clamps and hardware. Aluminum is great because it is cheap, fairly light, reasonably strong, and easily machinable. The only downside is that it doesn’t last forever being prone to corrosion and oxidization. Oxidation occurs when the surface of uncoated aluminum comes in contact with oxygen, forming a thin white coating, sort of like rust (but not rust as rust only occurs on steel and iron).

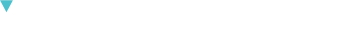

Aluminum and carbon do not play well together. Inside the 777 Boeing they actually keep carbon and aluminum from coming into direct contact. Why? Galvanic corrosion. Galvanic corrosion occurs when dissimilar metals come into contact with each other. One way to classify a metal is nobility, which is its ability to resist corrosion or oxidization. When a more noble metal comes into contact with a less noble metal, the naturally occurring corrosion of the less noble metal is accelerated.

Chart Source: Daniel Overbey

Threaded T47 bottom bracket inserts.

Integrated headset cups bonded in a frame.

Integrated headset cups bonded in a frame.

Carbon fiber is a good conductor, and, referring to the above chart, facilitates the movement of ions. When it comes into contact with a low nobility metal, like aluminum, it greatly accelerates corrosion. This corrosion can be slowed or even impeded by coating, anodizing, or sealing the aluminum, creating a barrier between the carbon and raw alumium. This is how it is possible to bolt a carbon handlebar to an aluminum stem, or press an aluminum headset into a carbon head tube. But, it is very difficult to create an enduring, structural carbon to aluminum bond.

Every part of the RM3 that is metal, including the threaded dropout inserts, threaded fork inserts for the axle and disc brake mounts, and threaded T47 bottom bracket inserts are made of titanium. The cups bonded to the inside of the head tube that carry the headset bearings – titanium.

I love titanium for its strength to weight ratio AND nobility. Long after you’re dead and decomposed aliens will be riding around on your Argonaut having a grand ole time.

Thanks for reading.