Carbon fiber isn’t just light and stiff—it’s tunable, directional, and purpose-built. At Argonaut, it’s the key to designing a ride that disappears under you while delivering total control.

Rethinking Performance on Two Wheels

The cycling industry has spent the last two decades equating performance with two metrics: stiffness and weight. But the truth is, a bike can be both stiff and light—and still ride like garbage.

Performance isn’t what looks good on a spec sheet. It’s what happens when you’re four days into a riding trip in the Alps, 80 miles into a big day, and the road kicks up again. The real test isn’t how quickly a frame transfers watts in a lab—it’s whether it helps you keep going when fatigue sets in.

At Argonaut, we define performance as the absence of interference. The bike shouldn’t fight you. It should support you—on climbs, on descents, through corners, and over unpredictable roads. That’s why we work with carbon fiber. Not because it’s trendy or easy, but because it’s the only material that gives us the design freedom to build a bike that adapts to you.

What Makes Carbon Fiber Unique?

At the heart of carbon’s advantage is one property: anisotropy. Unlike metals, which are isotropic and have uniform mechanical behavior in all directions, carbon fiber’s stiffness and strength depend entirely on the direction of the fibers. That means we can build structural bias into the material itself. We can design for specific loads, specific zones, and specific rider inputs.

This isn’t theoretical. We control this directional behavior through the layup process—orienting individual fiber plies at precise angles to tune for torsional rigidity, lateral stiffness, or vertical compliance depending on the location. A titanium or steel tube will give you the same characteristics from every angle. That might make manufacturing simpler, but it locks the builder into broad compromises: compliance comes at the cost of stiffness; stiffness at the cost of comfort.

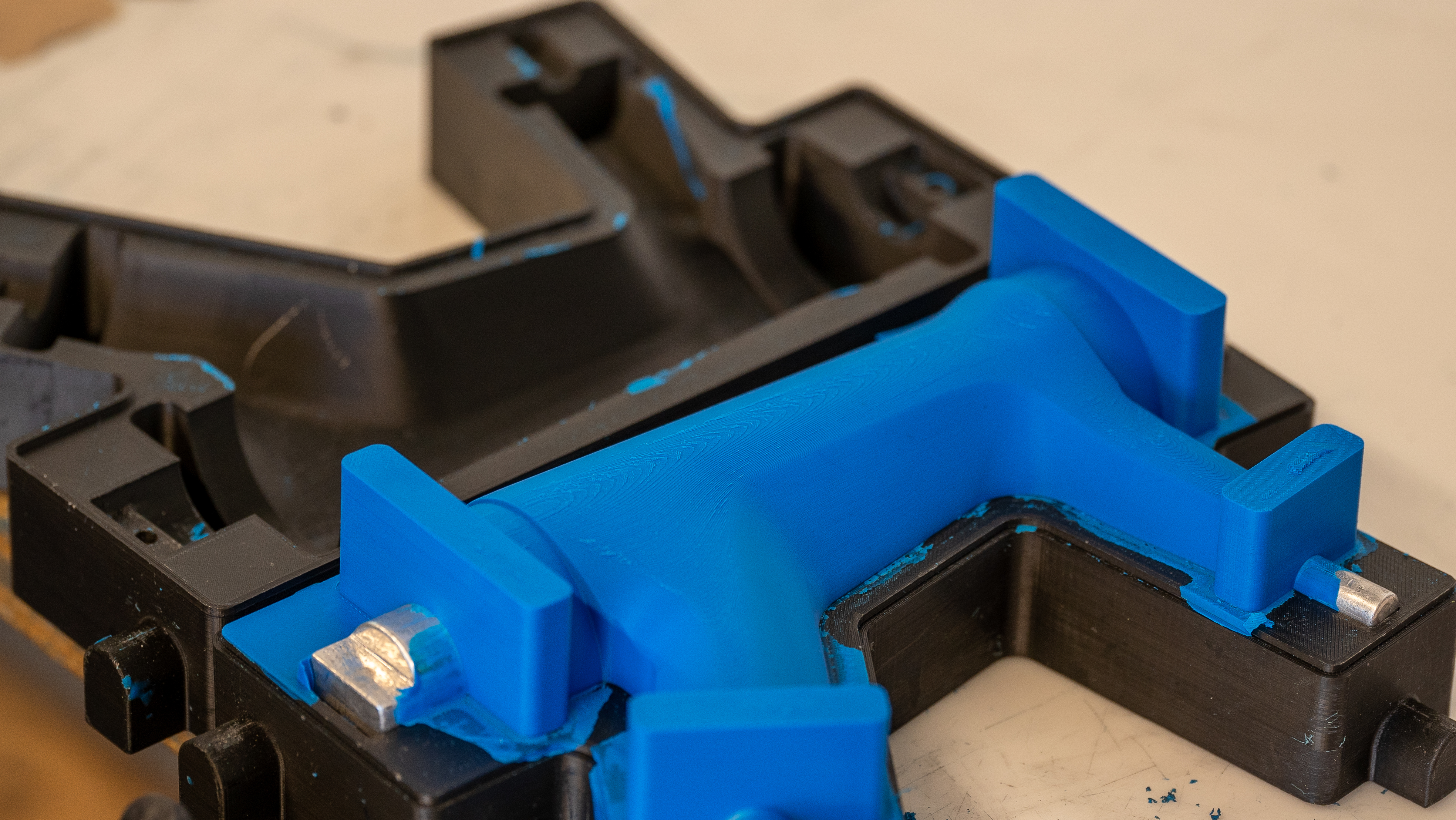

With carbon, you’re not stuck making those trade-offs. We can build a bottom bracket area that’s torsionally rigid without transmitting harshness to the saddle. We can create seat stays that flex subtly under vertical loads but remain laterally stiff in a sprint. And because we build all of our carbon sub-assemblies in-house, we’re able to control not just the material, but its behavior—ply by ply, part by part.

Layup as Suspension: How We Tune the Ride

Think of our layup as a form of passive suspension. Not the kind with linkages and air shocks, but the kind that’s engineered invisibly into the structure of the bike itself.

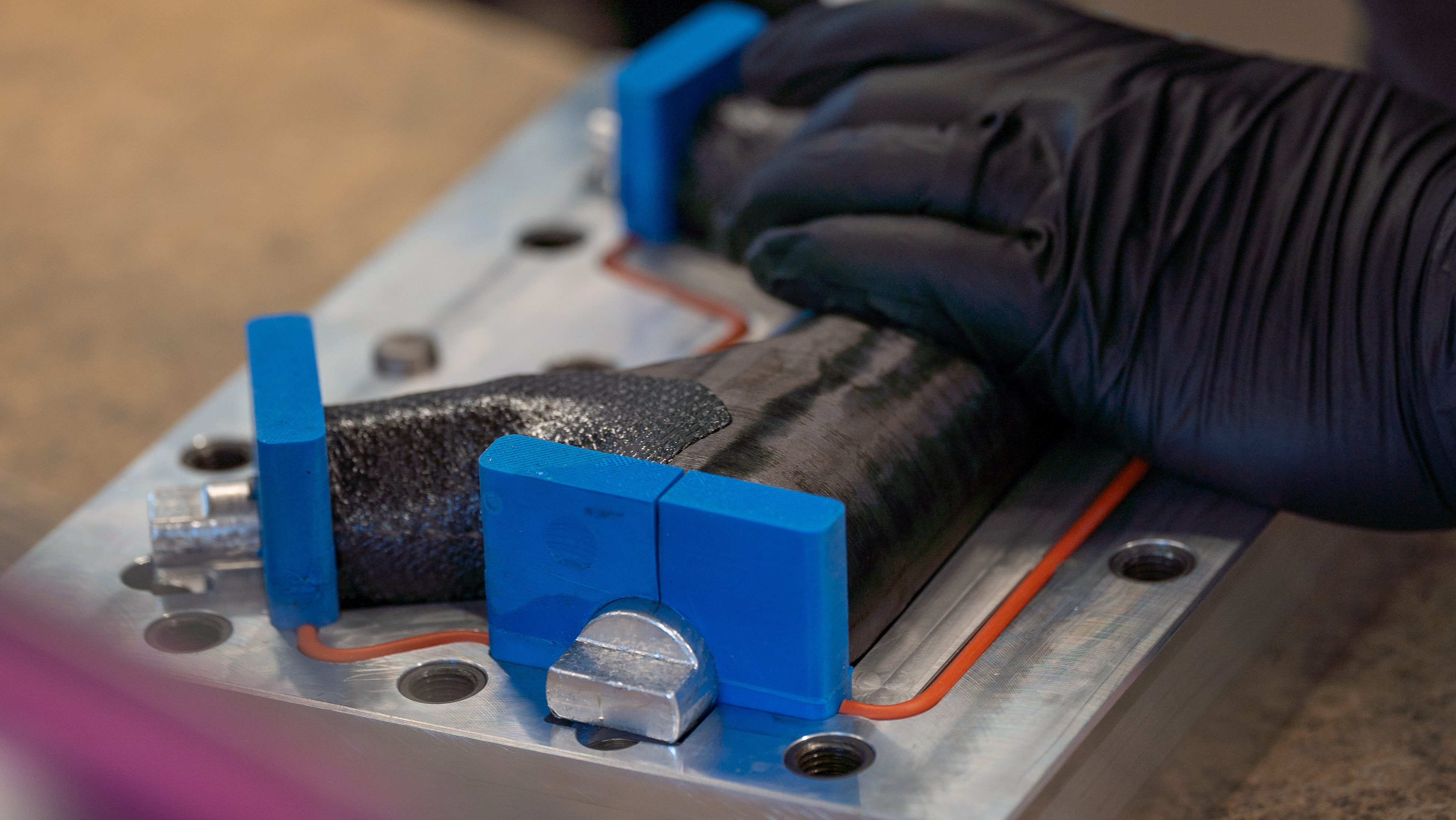

Every ply of carbon fiber in an Argonaut frame is placed by hand under tension. We choose fiber weights, angles, and overlap patterns based on the frame zone and expected forces in that area. At critical interfaces like the head tube junction or chainstay yoke, we increase compaction pressure and use specific fiber types to manage both peak load and long-term durability.

This is how we tune for ride feel—not by guessing, but by building in the behaviors we want to see. Want a front end that’s razor sharp in corners but still eats chatter on chip seal descents? That’s a layup schedule. Want the seat tube to offer subtle vertical give but retain pedaling efficiency? Layup. Want consistent performance across sizes without changing geometries? Layup.

This approach doesn’t just give you a "good ride." It gives you a designed ride—one that behaves predictably, responds instantly, and stays composed when your body starts to fade.

Why Comfort Alone Doesn’t Cut It

We hear it all the time: “Steel is more comfortable.” Or, “Titanium rides so smooth.” And that’s true—both metals offer a plush feel by virtue of their material properties and lower modulus. But that comfort comes at a cost.

Steel and titanium frames flex globally—they don’t differentiate between vertical inputs and lateral ones. The entire structure moves, which softens the ride but dulls power transfer and responsiveness. That’s fine for a Sunday cruise, but if you're descending switchbacks at speed or trying to hold a line through rough pavement in a crosswind, you want something more precise.

Carbon lets us isolate these behaviors. It gives us compliance in one direction and stiffness in another, depending on how we build it. The result isn’t just a comfy bike—it’s a bike that responds without punishing you. You don’t give up efficiency for smoothness. You get both.

Why We Don’t Use 3D Printed Titanium (Yet)

Titanium is a great material. And additive manufacturing has opened up some wild possibilities in frame design. But at this point, 3D-printed Ti doesn’t give us the control we demand over the ride.

The grain structure of printed titanium behaves differently than forged or butted tubing. It’s also more difficult to manipulate consistently at the wall thicknesses we’d need to match our current frame designs. Even with clever lattice structures or exotic shapes, we’re still dealing with an isotropic material that can’t match the directional tuning of carbon.

More importantly, we’d be handing over part of the ride quality to the printer. At Argonaut, we maintain full control over every variable—from fiber orientation to frame alignment to surface finish. Until additive manufacturing gives us that same level of input, we’re sticking with the material that gives us total control from start to finish.

Engineering Support, Not Resistance

The most misunderstood trait of a high-performance bike is its supportiveness. That word doesn’t show up on spec sheets, but it shows up in your legs at mile 70. A well-engineered carbon frame supports your body by dampening vibration, resisting torsional deflection, and returning energy predictably with each pedal stroke.

Road vibration isn’t just annoying—it’s cumulative damage. It creeps into your hands, lower back, and quads, making every mile feel longer. Our layup kills that noise before it ever reaches you. And because we do it without robbing the frame of stiffness or agility, you arrive at the end of the ride with energy to spare—and without needing a chiropractor.

We’re not interested in building the stiffest or lightest bike on the market. We’re interested in building the best-riding bike—one that lets you feel connected to the road, stable in the corners, and fresh enough to ride again tomorrow.

Performance, Reimagined

Carbon fiber isn’t the only way to make a bike—but it’s the only way to make this bike.

When you design for ride quality first—and when you build every piece of the bike in-house, with obsessive control over geometry, alignment, layup, and finish—carbon becomes less a material than a tool. It’s what lets us create a bike that acts like an extension of your body, not a piece of equipment you have to manage.

Forget modulus. Forget lab charts. The real performance gain is a bike that supports you deeper into the ride—when you’re tired, when the road gets rough, and when you want one less thing to think about.

That’s why we choose carbon. That’s why we build the way we do. And that’s why our bikes ride like nothing else.