Designed for you

Aluminum Molds

Where it all begins.

If most people saw the large chunks of very heavy 7,000 series aluminium sitting in our machine shop, they would have a hard time connecting the dots to the super light, perfect carbon parts being produced 30ft away. But, this is where every custom Argonaut is born, straight from the mold.

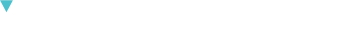

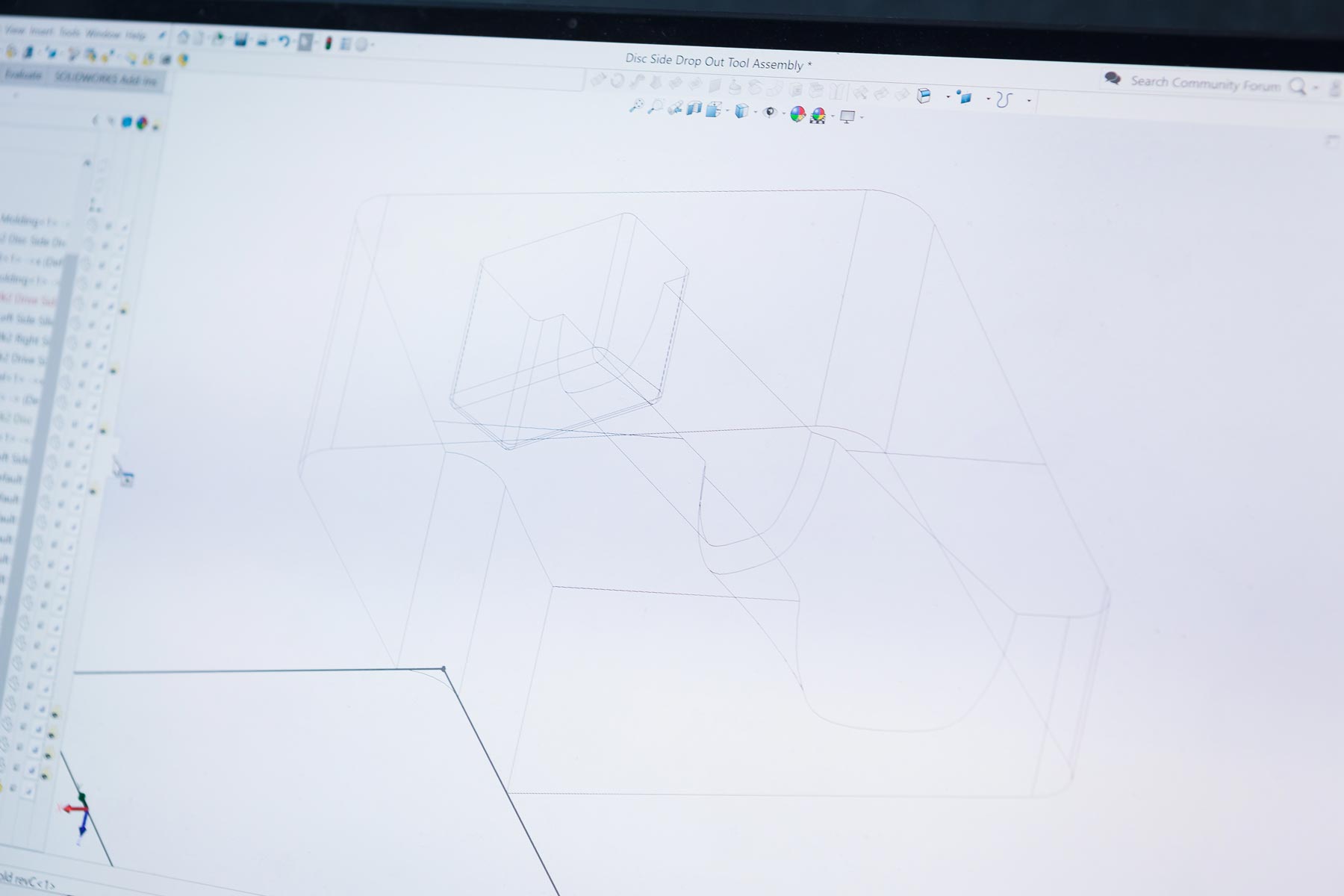

Creating a design in a computer, whether it be a bicycle or piece of furniture, is like designing a puzzle. Whoever’s job it is to turn that design into a physical thing has to solve that puzzle. The better that person is at solving puzzles the faster they’re able to make the physical thing with fewer tools and better use of material. This is effectively the relationship of the machinist to the designer. The designer makes the puzzle, and the machinist solves it.

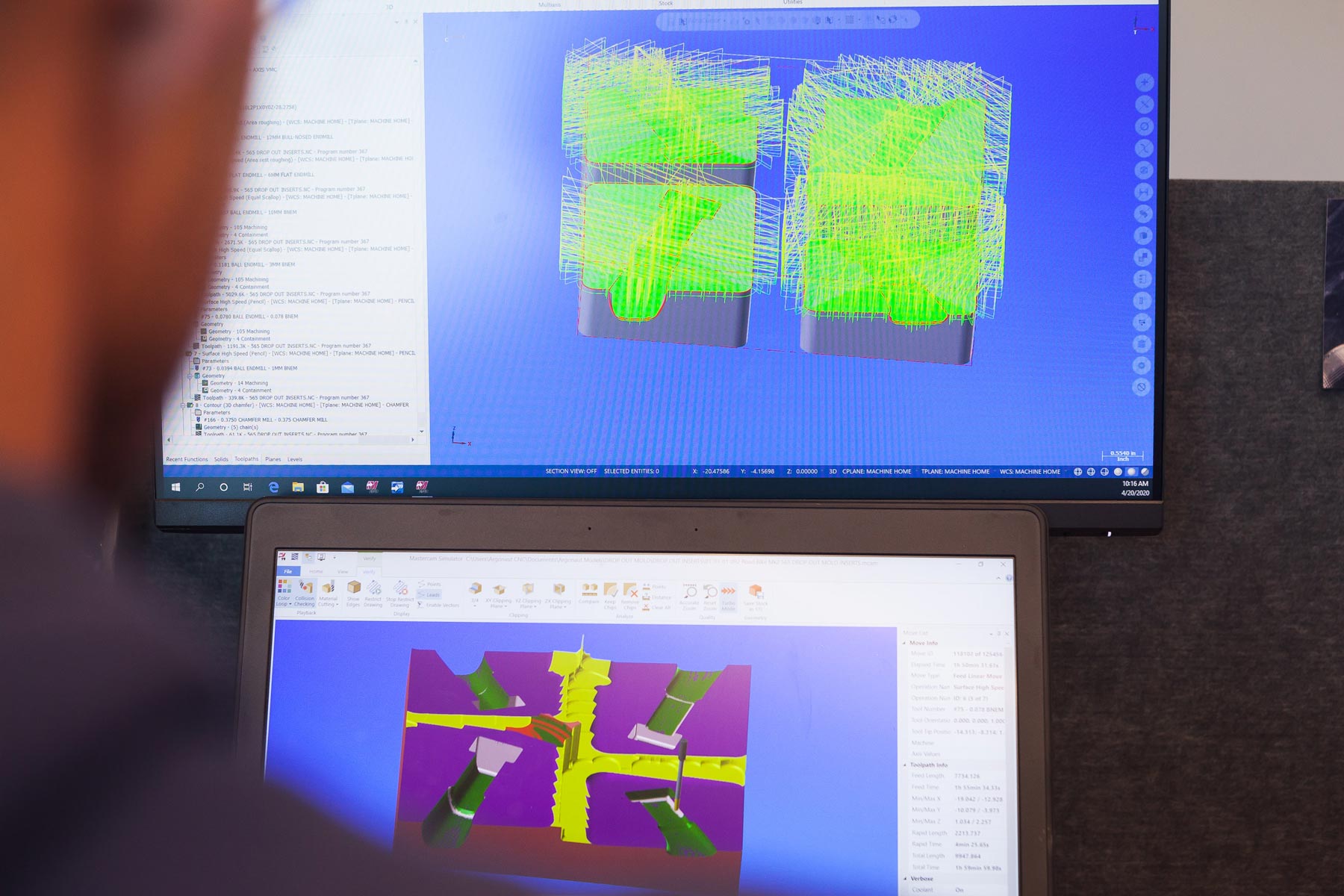

Argonaut has invested in a state of the art CNC or computer numerical control, to help execute the solution quickly and reliably. And while producing beautiful Aluminium molds may look simple when finished, the process and programming it takes to get there is actually rather nuanced and complicated. Having a skilled machinist is crucial to this process and some might even say it’s like an artist with a paint brush only, Mike, our machinist, can cast beautiful strokes using his brush (CNC) on the canvas (Raw Aluminium) to produce the beautiful molds.

Being able to machine our own molds sets us apart in the bicycle industry and puts us among only a few bicycle companies with this capability.

Step 1

Start with Raw Aluminium

Step 2

Design Head Tube, Seat Cluster, and Bottom Bracket in CAD

Step 3

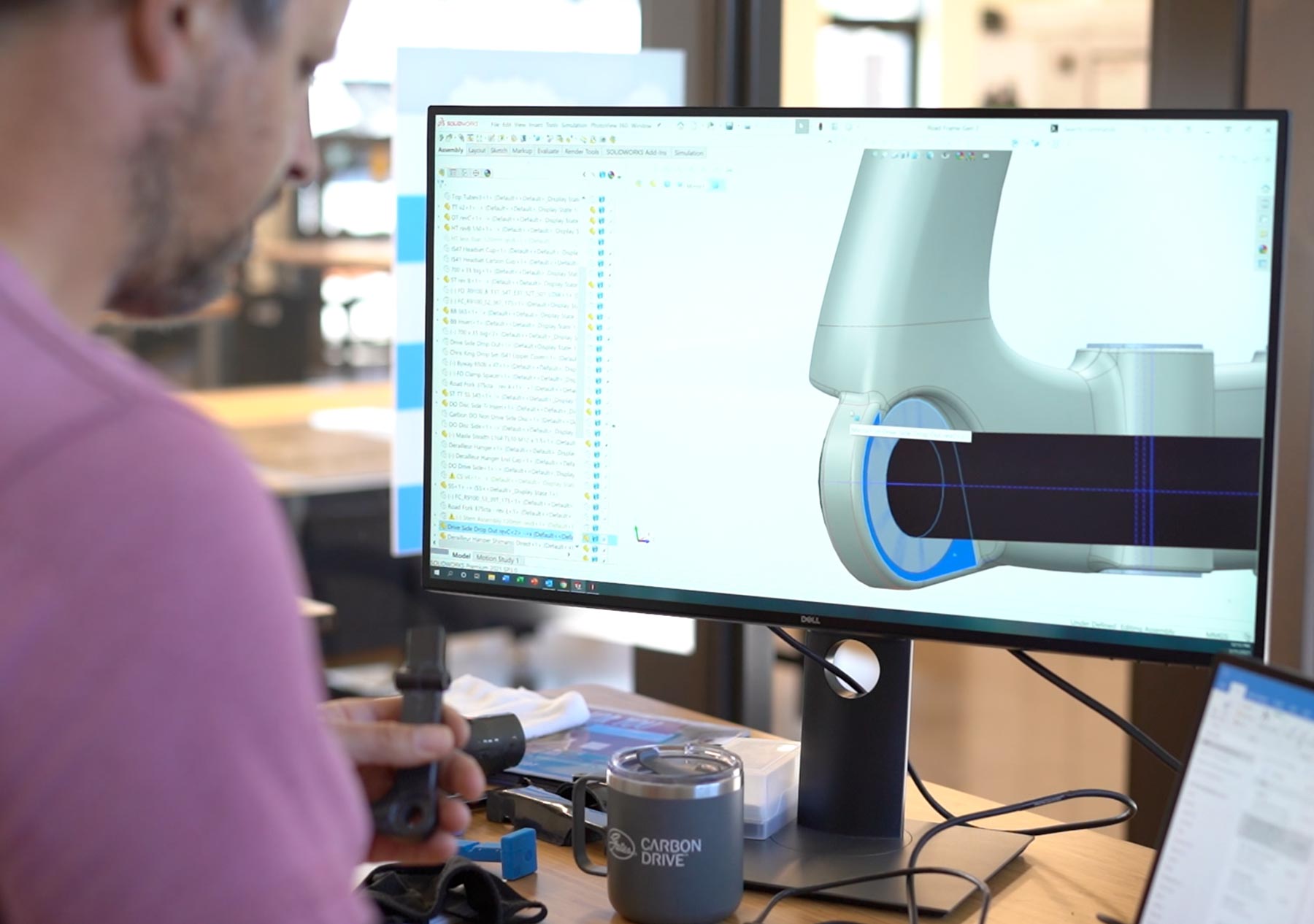

Review all Designs

Step 4

Translate CAD designs into CNC language

Step 6

Program all the thousands of pathways for cutting the raw aluminium

Step 7

Cut Raw Aluminium using various bits

Step 8

Clean molds and polish

Step 9

Ready for making carbon parts in lay up.