A better way

High Pressure Silicon Molding

Current Industry Problem

Fiber Distortion

One of the major flaws in current carbon bicycle frame fabrication is that the carbon is laid up on very limp mandrels. Often this is just the bare airbag of the internal inflatable bladder. The junctions will sometimes have molded and shaped mandrels, but again, these must be thin in order to allow the bladder expansion inside the mold during the curing process. Because of the amount of growth this bladder sees internally during the cure cycle, fiber orientation becomes difficult to control, as the loose bladder will push carbon any direction it wants as it expands under the air pressure being pumped into it. This causes significant fiber distortion and can change the strength of the part being molded substantially. Current carbon vendors increase wall thickness as a method of combating this fiber distortion in order to add a margin of safety to their parts, since they can’t guarantee which direction the bladder will push the carbon on each subsequent layup and cure cycle. It all depends on how the bladder inside expands and it’s different every time.

Our Solve

HPSM

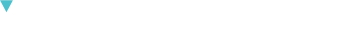

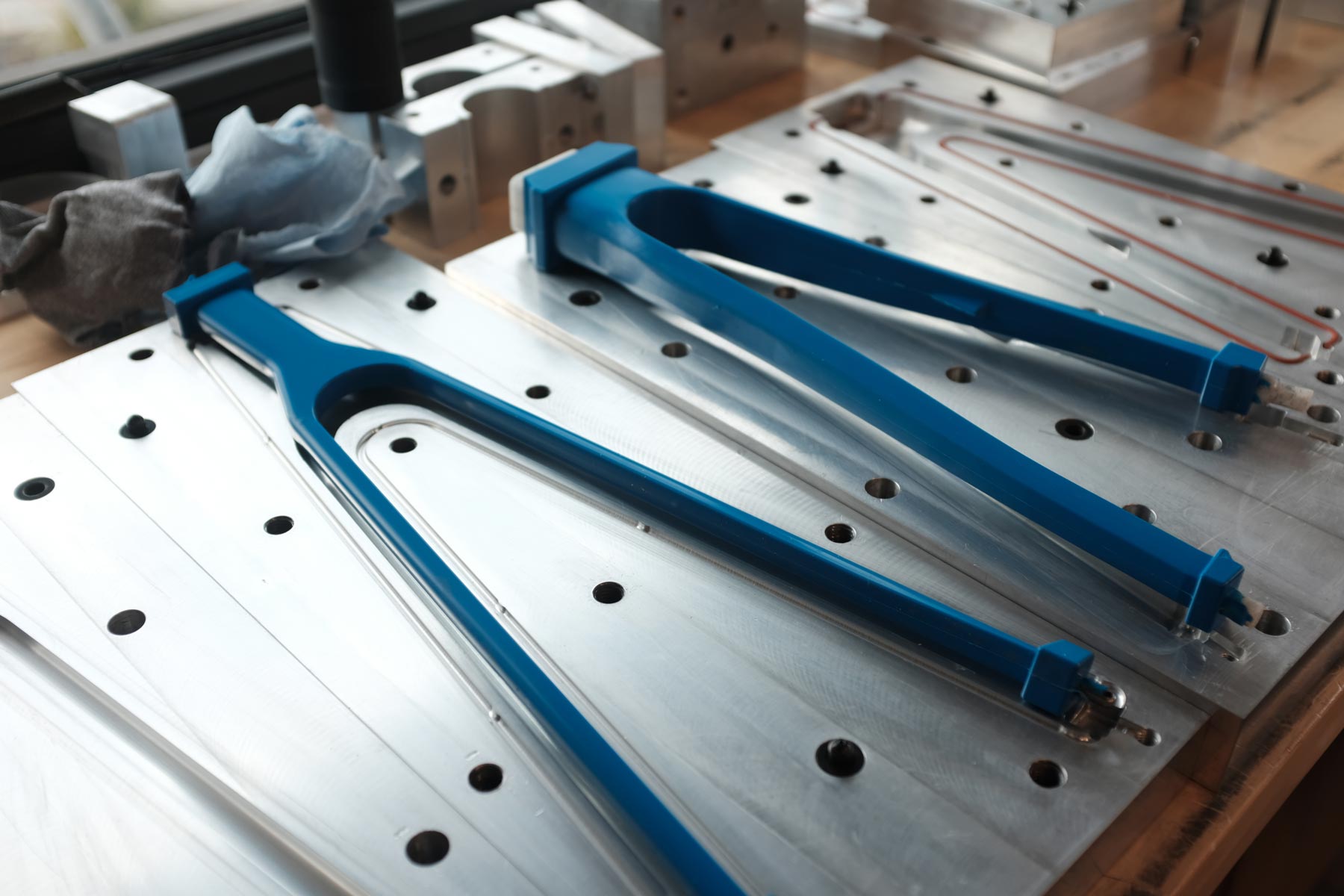

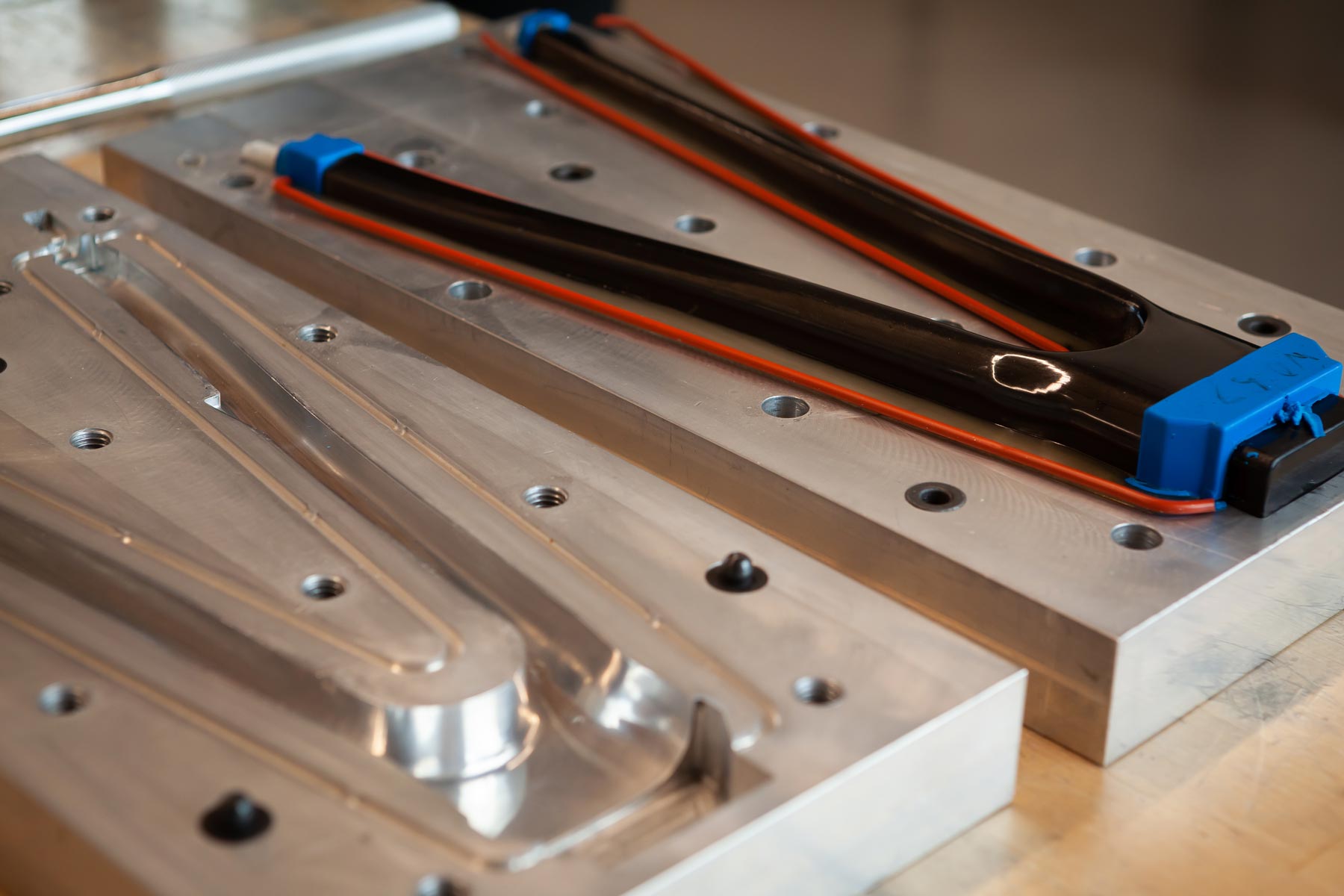

We landed on HPSM, or HIGH PRESSURE SILICONE MOLDING. It’s a patented take on trapped rubber molding and removes the internal bladder altogether and replaces it with a silicone structure that is being carried by an alloy skeleton. During the cure cycle, this silicone has a CTE (coefficient of thermal expansion) that increases internal pressure inside the mold. We control this pressure by the size and amount of silicone in relation to the skeleton. O-rings surround the part being cured and seal the mold, keeping resin trapped into the system and keeping internal pressures high. Once the part is cured, we remove the skeletons and internal silicone structure and are left with a perfect part. There are NO voids, pin-holes, or other structural flaws in any of the parts coming out of our oven.