TECHNOLOGY

Solo Off The Front.

High Pressure Silicon Molding

First of Its Kind.

Using composite-industry leaders as a benchmark, we developed our own patented silicone molding process—no fillers, no folded fibers or ply distortion, zero voids, and cleaner manufacturing. Today, we are unparalleled in our ability to produce ultrastrong, ultralight, nuanced carbon components with seamless integrity inside and out.

High Pressure Silicon Molding

First of Its Kind.

Using composite-industry leaders as a benchmark, we developed our own patented silicone molding process—no fillers, no folded fibers or ply distortion, zero voids, and cleaner manufacturing. Today, we are unparalleled in our ability to produce ultrastrong, ultralight, nuanced carbon components with seamless integrity inside and out.

High Pressure Silicon Molding

First of Its Kind.

Using composite-industry leaders as a benchmark, we developed our own patented silicone molding process—no fillers, no folded fibers or ply distortion, zero voids, and cleaner manufacturing. Today, we are unparalleled in our ability to produce ultrastrong, ultralight, nuanced carbon components with seamless integrity inside and out.

High Pressure Silicon Molding

First of Its Kind.

Using composite-industry leaders as a benchmark, we developed our own patented silicone molding process—no fillers, no folded fibers or ply distortion, zero voids, and cleaner manufacturing. Today, we are unparalleled in our ability to produce ultrastrong, ultralight, nuanced carbon components with seamless integrity inside and out.

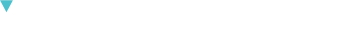

CNC

Modeled After You.

Built entirely in-house in Bend, Oregon, your Argo goes from raw carbon fiber to full-fledged bicycle in roughly 32 hours. Whether pre-curated or full-custom, your bike begins with CNC-cut tooling designed specifically for you and continues with bespoke components handbuilt according to your blueprint.

Custom Tubes

Purpose-Built, Inside And Out.

By bringing the power of unidirectional carbon into conversation with your output metrics and riding style, we’re able to custom-tailor your layup and alter the stiffness of each carbon tube. The result is a ride that responds to your every move—intimately and with finesse.

Carbon Manufacturing

Limitless Potential.

Heavily utilized in aerospace and F1 fabrication, unidirectional carbon is unsurpassed in its functionality, malleability, and weight. Here, it’s what allows us to handcraft layer by carbon layer, focus on strength versus grams, and calibrate with finite precision—all according to you.

Paint

Style For Days.

Together with our in-house art director, Chris, you’ll go through our custom paint design process and choose either an Argo-curated palette or full-tilt custom paint scheme. Using high-quality, ultra-durable paints, we’ll collaborate to create what feels like a dream—your dream—and rides like one too.