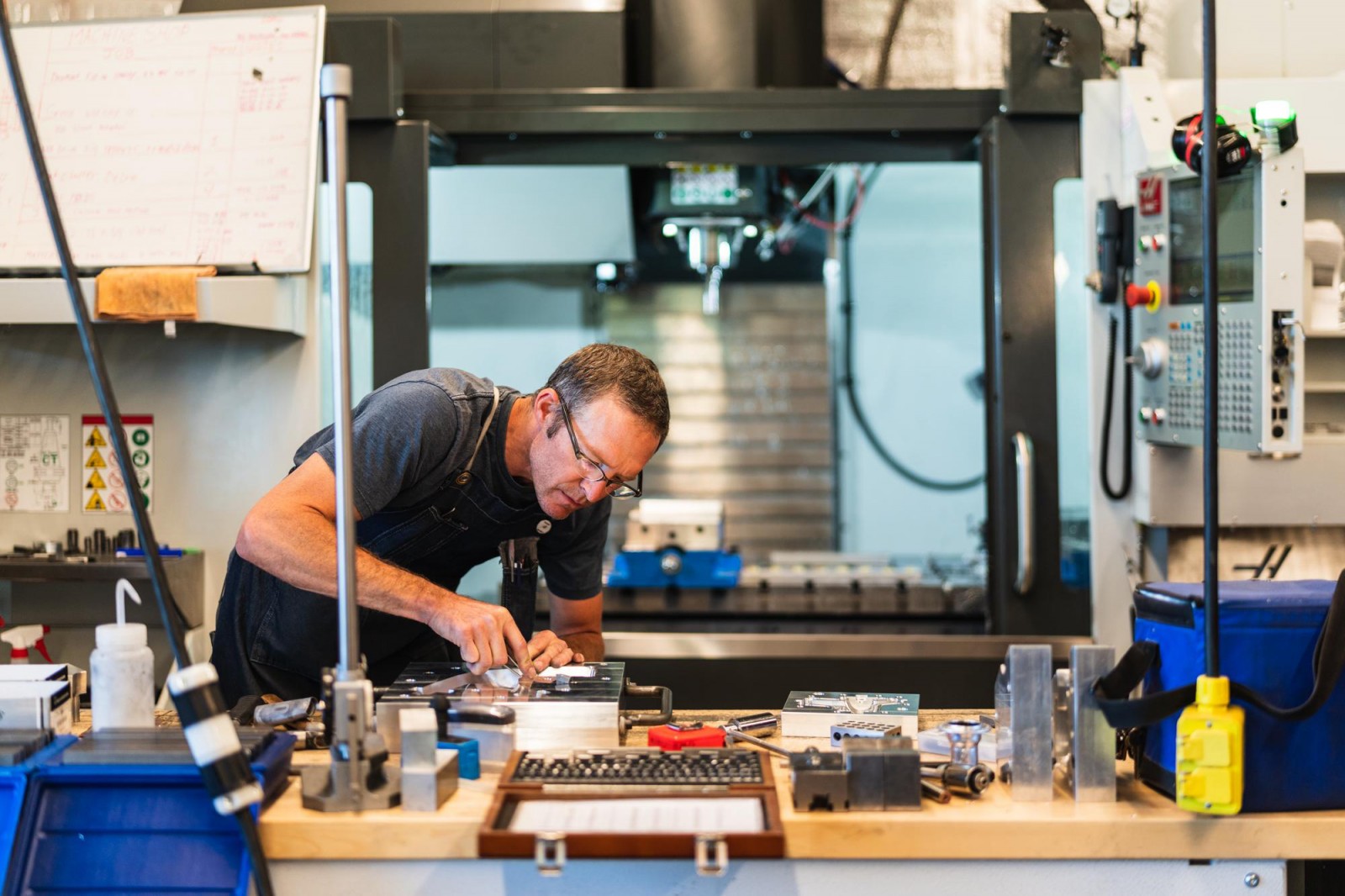

While in Bend, OR, recently, Josh caught up with the Argonaut Cycles team for a tour of their facilities and sat down for an interview with founder and designer Ben Farver. The conversation covers the brand’s fully custom in-house carbon frame and component production methods and more. Below, find Argonaut’s GR3 introduction, Josh’s interview with Ben, and an extensive photo gallery detailing the Argonaut fabrication process!

Argonaut Cycles continues to push the envelope of what is possible with carbon fiber in the release of the GR3. At the core of the GR3 is the GravelFirst geometry. Road bike geometry hasn’t changed much in 20 years. Cross-bike geometry hasn’t changed much in the last 15 years. Gravel geometry has changed significantly in the last five years and often in divergent ways. The first gravel bikes were cross bikes with disc brakes and tubeless tires, as are many current gravel bikes.

Born from the desire to address the needs of the modern gravel cyclist specifically, the GR3 is a major leap forward in gravel bike design, built for everything found on a typical “gravel” ride: a bit of road, a bit of smooth gravel, a bit of NOT smooth gravel, and a bit of single track. Ample tire clearance allows one to run up to a 50c tire, but with an industry best 415mm long chainstay the bike jumps at every pedal stroke and carves through every turn. The low, 75mm bottom bracket drop, and slack 68.5º front end allows you to fly downhill, skip over ruts and rip through corners faster than you ever thought possible. A PR smashing machine, the Argonaut GR3.

Click here to continue reading