Improving upon the last iteration of the Argonaut custom road bike was a tall order and required nothing short of a comprehensive overhaul of every aspect of Argonaut’s design and manufacturing techniques.The articles below give you a glimpse into our process and technologies that have allowed us to push what custom carbon bikes can be.

CNC Router

8.4.2020

I’m writing this sitting in an airport watching the Strade Bianchi live. What?! Air travel and pro cycling? The world is still pretty scary compared to seven months ago, but it sure is nice to see my favorite sport back in action. And crazy news flash – racers in the Strade Bianchi are riding gravel on 28c tires. Who in their right mind would ride gravel on anything smaller than a 40? These guys must have not gotten the memo that in order to ride a bike on a dirt road you need at least a 38c tire and a handmade handlebar bag stuffed with snacks and a little weed. Hahaha, I kid, I kid. Who doesn’t like a bag full of snacks and a little weed on the front of their bike?But the point of this Tech Tuesday isn’t to critique what’s cool – or high rather – in the cycling industry, it is to talk about the tech that goes into building our frames….Read More>

An Argument for Disc Brakes

7.14.2020

The RM3 is only available as a disc brake road bike. Rim brakes as a whole are soon to go the way of the Dodo bird for road bikes, and here’s a quick list of reasons why….Read More>

Titanium

7.7.2020

I love titanium. Everything is better with titanium. I would put titanium on my breakfast cereal if there was a chance it would slowly turn me into something like Wolverine. It’s light, super strong, and extremely corrosion resistant. When aliens land on Earth long after humans have gone extinct our titanium implants will be the only evidence of our existence….Read More>

Clearance, Clarence!

6.30.2020

The term “quiver killer” is thrown around a lot these days, and refers to a bike that can serve the purposes of a cyclocross, gravel, or road bike all in one. Our own GR2 was meant to be this to some extent. The idea of having one bike to ride any surface other than technical MTB single track is certainly appealing….Read More>

RM3 Paint Design

6.23.2020

Chris Fitzpatrick wears a bunch of hats around here, but his primary responsibility as Art Director is all things aesthetic, including paint design. All the beautiful paint designs you’ve seen over the years are his doing, deftly executed by our painter, Matt….Read More>

Paint

6.16.2020

Painting a carbon fiber bicycle frame is alchemy. The process is a combination of chemistry and artistry where each process has its own technique and potential pitfall. A good painter does more than deftly apply material. A good painter knows how to fix a flaw or misstep without having to go back to square one….Read More>

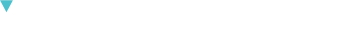

Frame Geometry

6.9.2020

What makes a custom bike custom? In the broader industry a bike can be called custom simply by being different than a company’s stock build. That is, someone buys a stock, production frameset and either builds it themselves with components of their choice, or a shop creates an a la carte build for them. The second layer is where our custom world starts – a bike made from scratch for the individual rider….Read More>

Testing

5.26.2020

Make it, break it, do it again. That pretty much sums up our testing protocol over the last three months. When the Argonaut team and I decided to take all composite production in-house it became apparent that robust and comprehensive impact and fatigue testing capabilities would be imperative….Read More>

Perfect Custom Carbon Bicycles

5.19.2020

For those that read last week’s Tech Tuesday titled Back to Tubes , I bet you thought we were going back to Tube to Tube style construction. Ha! Really?? No way, no how. The technology we’ve developed to make the frame junctions is unlike anything currently being done in the bicycle industry. To be honest, the composite technology most widely used to make bicycles is fairly antiquated. It is our goal here at Argonaut to utilize the most advanced technologies from the broader composite industry to create the best carbon fiber bicycle frame possible. In the case of the frame junctions, we’ve even created our own patent pending process….Read More>

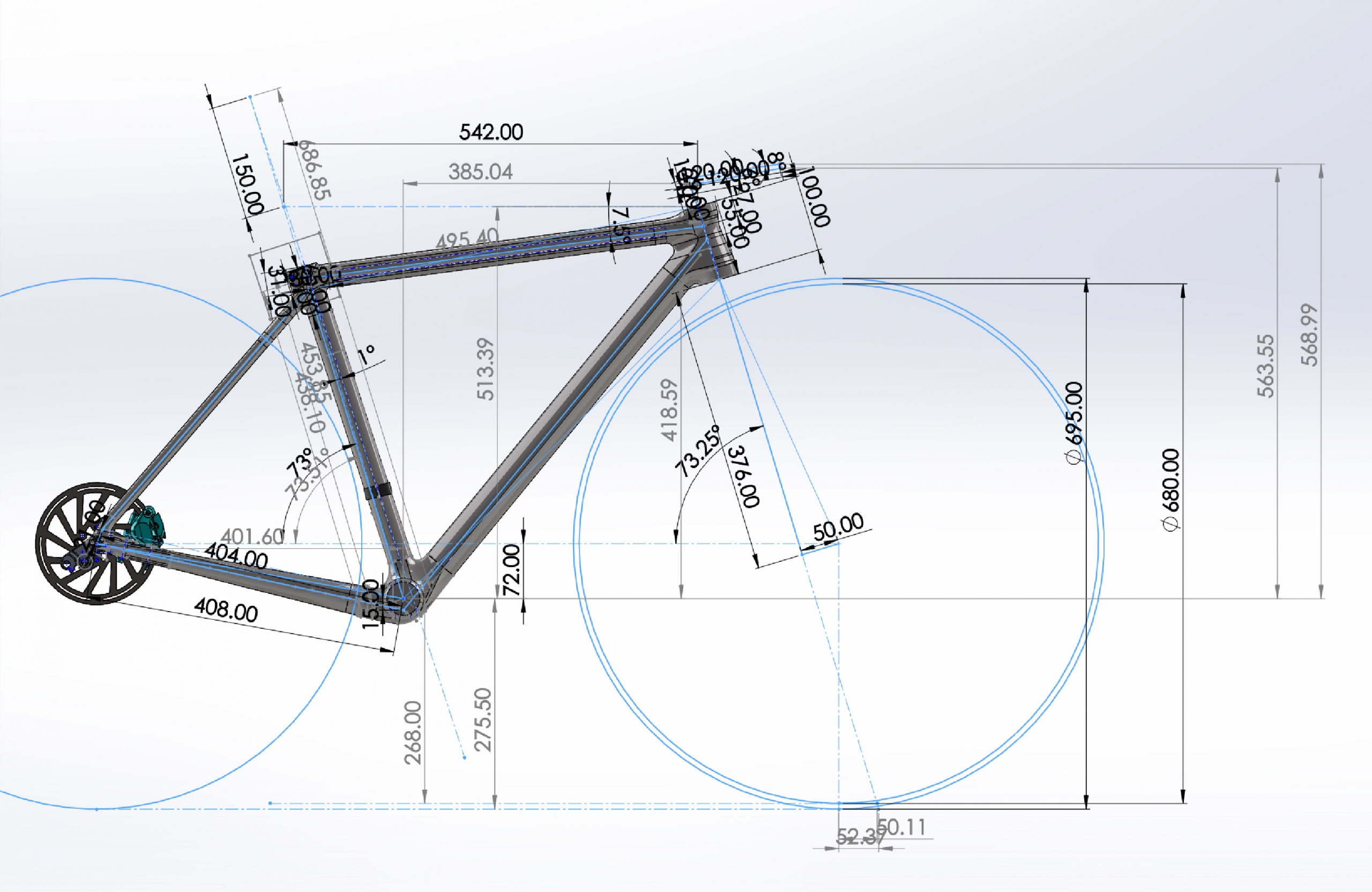

Back to Tubes

5.12.2020

There are many ways to make a bicycle. Each modality of construction is either driven by efficiency of construction or the material being used – and sometimes both. Steel bikes were originally brazed, but now mostly TIG welded. Titanium can ONLY be TIG welded, that is unless you’re Bruce Gordon and decide to make a lugged Ti bike, but I’m fairly certain he’s the only one that has pulled that off….Read More>

The Layup

4.28.2020

The thing that truly sets carbon fiber bicycles apart from their metal cousins is the ability to manipulate the material in a way that yields inconsistent flex characteristics dependent on the direction of force. If I’ve already lost you, sorry…. this Tech Tuesday is going to get granular. But that’s what you’re here for, right? I’m sure the kids are quietly doing their schoolwork and you’ve already got most of the cooking for the day prepped and ready to fire, so why not do a deep dive into the physics of composite bicycles?!….Read More>

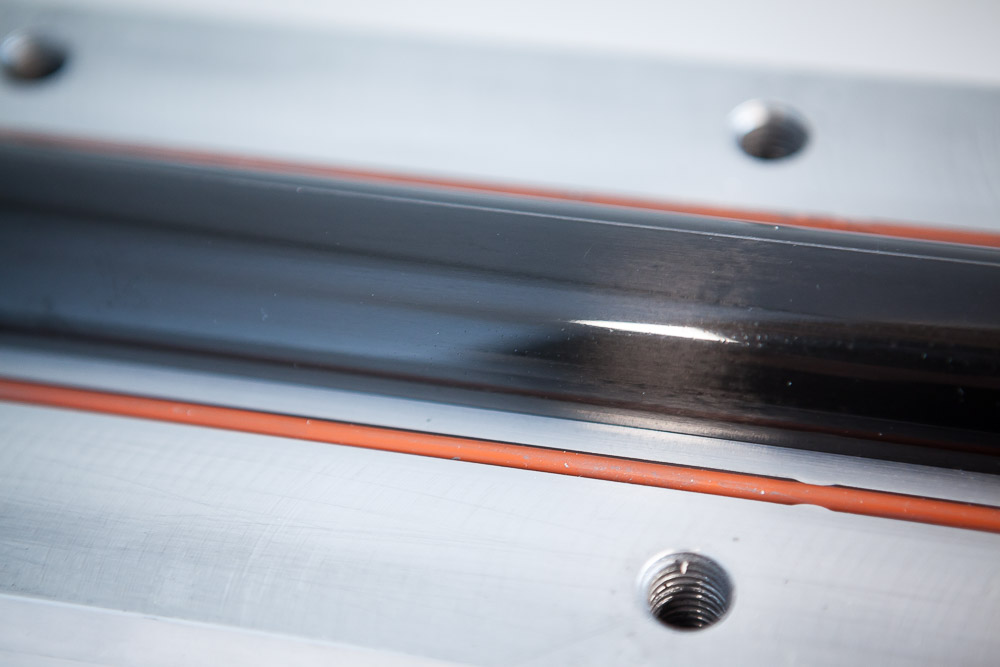

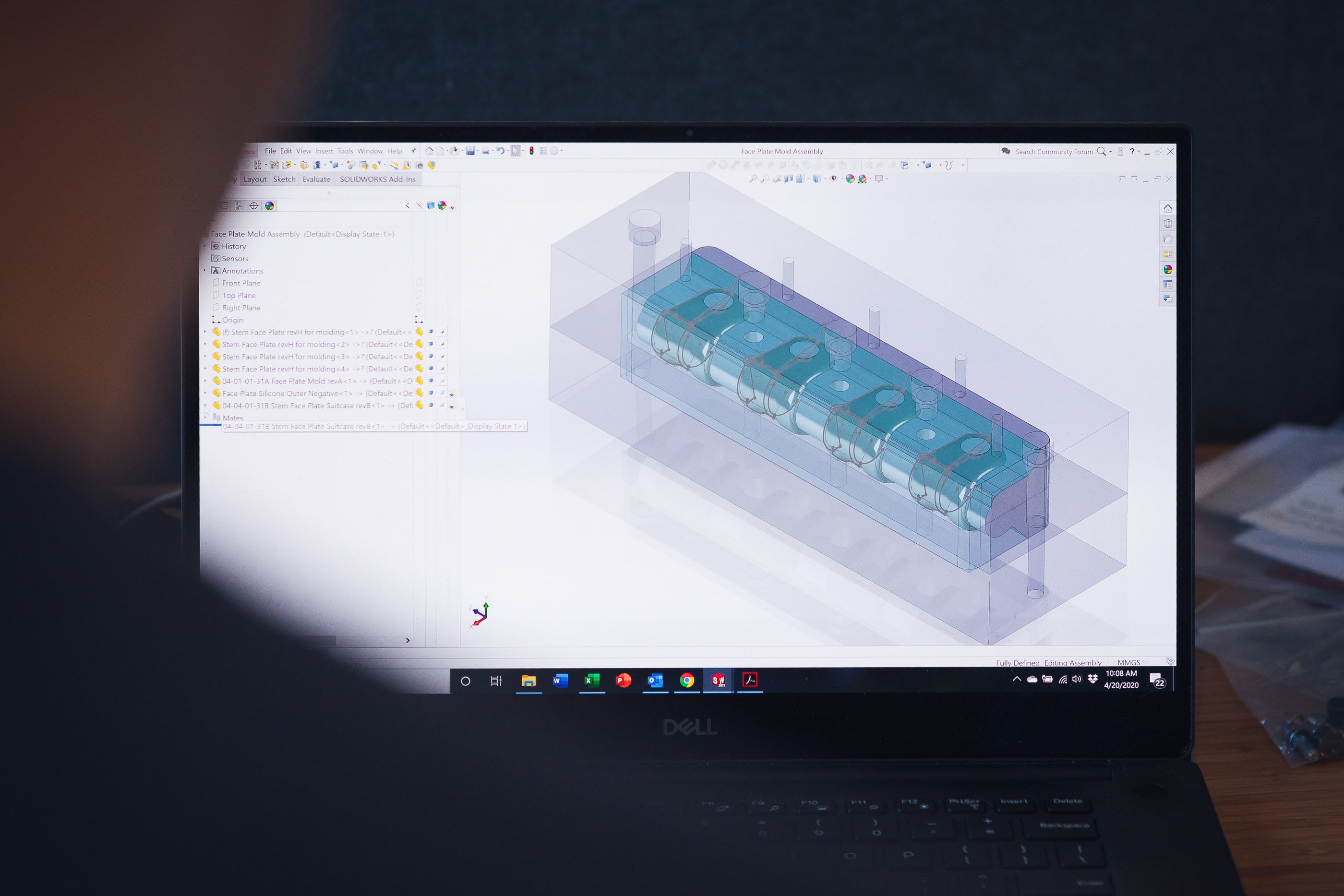

CNC Machining

4.21.2020

Creating a design in a computer, whether it be a bicycle or piece of furniture, is like designing a puzzle. Whoever’s job it is to turn that design into a physical thing has to solve that puzzle. The better that person is at solving puzzles the faster they’re able to make the physical thing with fewer tools and better use of material. This is effectively the relationship of the machinist to the designer. The designer makes the puzzle, and the machinist solves it….Read More>

WTF is CAD?!

4.14.2020

CAD, or computer aided design, is a term thrown around a lot, so I thought it pertinent to dive into what CAD design is, and why it is so important when it comes to making Argonaut bicycles. One of the primary reasons that the look of a bicycle has evolved from relatively straightforward, two triangles with round tubes, design to the wild, swoopy, flowy surfaces we see now is the broader industry’s move from metal to carbon fiber frames….Read More>

Behind the Curtain

3.31.2020

A quick history lesson for those that aren’t familiar….. when I switched from making steel frames to working with carbon I didn’t have the expertise or equipment to make carbon frames at the level I wanted. I got very lucky when I found an outstanding supplier just up the Columbia River from my small shop in Portland – Innovative Composite Engineering (or ICE) based in White Salmon, WA. It was with the help of ICE that I developed the first Argonaut carbon road frame, and from 2012 on we have had a great relationship. I am extremely grateful for everything that Steve Maier and the team at ICE helped me accomplish and taught me over these last eight years…. Read More>

Thanks.